Frequently Asked Questions

-

Cutting pads are used to break down, and level paintwork - this helps remove any defects in the paintwork such as swirls & scratches, but also gives the paint a deep clean, reviving lost gloss and clarity in the paintwork.

Cutting pads can be used in a variety of different applications. Most commonly, enthusiasts or detailers will use cutting pads in their initial polishing stage, helping to remove stubborn, deeper scratches and/or defects before following up with a finishing stage, if needed. They can also be used to assist in removing sanding marks, where a higher level of cut is required. -

For cutting pad size, it really depends on the size of the backing plate on your machine polisher. The general rule of thumb is, you want a cutting pad that is either the exact size of your backing plate or slightly larger. Smaller sized pads may ruin the balance of your machine and expose the backing plate which can potentially damage the paint.

Most of the cutting pads you see online taper slightly, so a 6.5" pad may have a surface are of 6.5" but will taper down nicely to suit a 6" backing plate.

If you are unsure of what size cutting pad to get or unsure what size backing plate is on your machine polisher, don't hesitate to contact us here. -

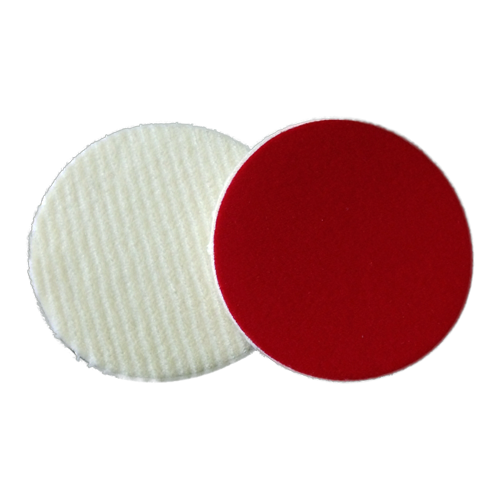

Fundamentally, the difference between foam, microfiber and wool cutting pads are simply what they are made of. The reason these 3 types of pads exist, is they offer different benefits.

Starting with foam pads , they are easier to use, and finish down with the best results. Most of the time, if you are a beginner to polishing, or looking for a 'one-step' solution, foam is generally your go-to pad. Professionals will still predominantly use these pads for their reliability, versatility and low cost.

Microfiber pads are the newest technology, and can provide a faster level of cut, which can make polishing more efficient. Microfiber pads are best used in combination with an air compressor, as you have to blow the pads out after each pass to ensure the fibres aren't matted with excess compound. Definitely worth a play around if you are a professional and looking to try to be as efficient as possible.

Wool pads are the older of the 3 types of pads. They provide arguably the highest level of cut. Their only negative is the wool is very aggressive and can sometimes result in quite a bit of hazing and marring to clean up after cutting - so a finishing stage is usually mandatory after using a wool pad for an intense cut.

-

Not always, and by no means is it 100% necessary to do so.

Using a cutting pad alongside a cutting compound means you are using aggressive abrasives to help break down the paint. The result of this 'cutting' action usually results in "haze" or "hazing" occurring on the surface of your paint.

"Haze" or "Hazing" is caused by microscopic scratches left over from the sheer aggression of the cutting abrasives used and often causes the paint to look foggy or hazy, hence the name.

To remove this fine level of haze, we recommend using a finishing pad with a finishing compound to remove the haze. On some of the harder paint systems you may find your cutting stage isn't producing any haze, this is fine and might mean that you won't need to finish down after cutting. -

You can use any compound with a cutting pad. But, when you do reach for the cutting pad, it's usually because you are looking for some serious bite to remove deeper scratches in your or the customers paint. With this is mind, cutting compounds are usually paired with cutting pads on most paint systems, and on softer paints, we usually use an intermediate compound like Scholl S20.

-

Cleaning your pads and maintaining them is actually very simple. There are 2 main elements when caring for your pads, first is to reduce the compound build up on the surface of the pad and the second is to give them a good clean!

To prevent compound build up, we recommend using a pad cleaning brush. These brushes aggravate the surface level compound and helps to reduce and remove any built up compound to ensure optimal performance for the next polishing stage. As compound seeps further into the pad, a deeper clean is recommended. This is where you will need to use a purpose built pad washer, washing detergent with a bucket or an all purpose cleaner to help break down then compound residue. Once this step has been completed, simply rinse off and squeeze the pads out under warm running water and allow them to dry away from direct sunlight.

To learn more about machine polishing pad care, click here.

Other products across buffing & polishing include intermediate pads, finishing pads, kits & pads stacks, microfiber pads, wool pads, and pad cleaning products.